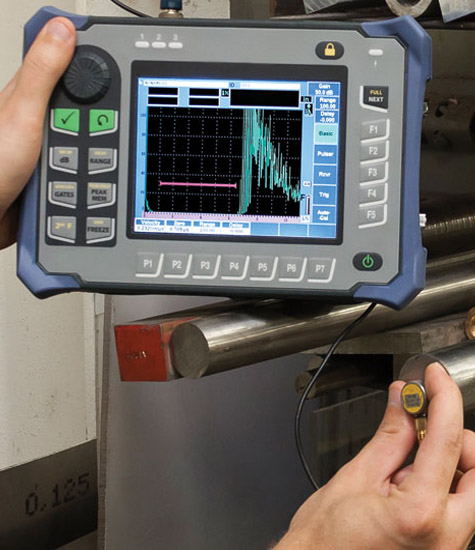

Ultrasonic inspection

Traditional Ultrasonic inspection uses high frequency sound energy to conduct examinations and perform measurements. Considerable information may be gathered during ultrasonic testing such as the presence of discontinuities, material or coating thickness. The detection and location of discontinuities is enabled by the interpretation of ultrasonic wave reflections generated by a transducer. These waves are introduced into a material and travel in a straight line and at a constant speed until they encounter a surface. The surface interface causes some of the wave energy to be reflected and the rest of it to be transmitted. The amount of reflected vs. transmitted energy is detected and provides information on the size of the reflector, & therefore the discontinuity encountered. Three basic ultrasonic techniques are commonly used: Pulse-echo and through transmission Normal/Angle Beam Contact and Immersion